Intereuropean News

Tire Technology Expo 2016

February 16-18, Hannover, Germany

INTEREUROPEAN S.r.l. has participated as exhibitor to the Tire Technology Expo 2016 in Hannover on February 16th-18th 2016.

At the exhibition the company presented:

- Latest generation Tire Building Machines, such as Uni-Stage TBM with 30 sec/tire cycle time that may use customer's standard uni-stage drums, and the Combi TBM (1st and 2nd Stage TBM combined into one fully automatic machine) with the cycle time of 35 seconds/tire and using standard 1st and 2nd Stage building and shaping drums.

- Ply Cutting and Splicing Lines with fully automatic bias cutter and splicer for fabric cord ply that can reach 20 splices per minute at 90 degrees fixed angle and 15 splices per minute in fully automatic mode for the 40-90 degrees version.

- Bead Apexing Lines

- Complete machinery range for production of Air-Springs.

The show has generated a lot of interest in INTEREUROPEAN's newly developped machinery by the major tire companies.

MACHINERY INNOVATION

by INTEREUROPEAN

Tire Technology International Magazine, October 2015 issue

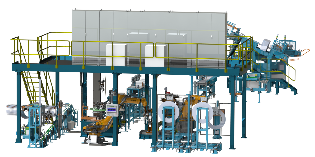

The article is dedicated to the new generation of Fully Automatic Combi Tire Buillding Machines with 35 seconds / tire cycle time.

These machines are designed to replace the existing 1st and 2nd Stage TBMs by removing all the manual operations and making the tire assembly process trully automatic. The Combi TBM is ran by just one operator and it is 100% compatible with the existing 1st & 2nd Stage tire assembling process. It can be used to produce tire sizes covering all the PCR and LT tires up to 24in, including ultra-high performance tires. Every 35 seconds a finished green tire is coming out of the machine, while the operator simply supervises the process.

This is a perfect solution for all those tire companies who want to upgrade their tire building area to the modern high performance fully automatic version tire building machines without changing the existing process and specifications.

Other innovations include Uni-Stage TBM with 30 seconds/tire cycle time and fully automatic Bead Apexing Lines for apex extrusion and application on the beads. Read the article on the left for more information.

Tire Technology International Awards for Innovation and Excellence 2015

Further to the highly innovative Uni-Stage Tire Building System presentation at the end of last year, INTEREUROPEAN S.r.l. was shortlisted among the finalists of the Tire Manufacturing Innovation of the Year 2015 award.

This is an important sign of high international recognition of the technological achievements of the company in the tire building machinery development field.

Tire Technology Expo 2015

Cologne, Germany

INTEREUROPEAN S.r.l. is participating as exhibitor to the Tire Technology Expo 2014 in Cologne, Gemany on February 10-12th 2015.

Visit us at our Stand N.2160.

Uni-Stage TBM

by INTEREUROPEAN

Tire Technology International Magazine, November 2014 issue

The article is dedicated to the new generation of Fully Automatic Uni-Stage Tire Buillding Machines with 30 seconds/green tire cycle time.

The machine can be used to produce tire sizes covering all the PCR and LT tires up to 24in, including ultra-high performance tires.

Various lay-out configurations and drum type options are available to suit any customer's specs

New Combi TBM

Green Tire in 35 seconds

Tire Technology International Magazine, July 2014 issue

The article is dedicated to the new generation of Fully Automatic Tire Buillding Machines with 35 seconds/green tire cycle time.

Currently INTEREUROPEAN offers the choice of 3 different types of tire building machines:

1) 1 st & 2 nd Stage TBM

Cycle time 45 sec. + manual carcass transfer from 1 st to 2 nd stage + manual bead setting

2) Combined TBM

Cycle time 35 sec. (including automatic carcass transfer from 1 st to 2 nd stage & automatic bead setting

3) Uni-Stage TBM

Cycle time 30 sec./40sec. depending on online/offline preassembly of IL+SW. Fully automatic operation

Tire Technology Expo 2014

Cologne, Germany

INTEREUROPEAN S.r.l. has participated as exhibitor to the Tire Technology Expo 2014 in Cologne, Gemany in February 2014.

At the exhibition the company has presented the latest machinery designs for PCR/LT tyres, as well as complete machinery range for production of Air-Springs.

Revolutionary system for Air Springs manufacturing

Tire Technology International Magazine,, November 2012 issue

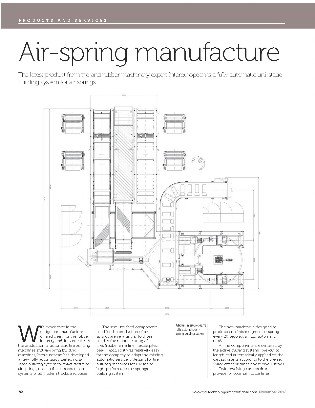

INTEREUROPEAN has finished development of a new fully automatic Uni-Stage Air Springs Building system, assembling a complete air spring in 20 seconds!

For quick material spool changes the system is provided with double sets of let-off carriages (or cassettes, depending on what the customer's standard is), which allows to change bobbins and thread the material off-line. The let-off carriage replacement in the machine and material ends splicing takes only around 1 minute.

Considering 4 shifts per day (6 hours each) operation and considering 1 hour per shift machine down time for spool changes, operator breaks etc, there are 20 hours per day of continuous machine operation at 3 air springs per minute speed, which equals to 3.600 air springs per day maximum output!

All the components of this new system were tested by INTEREUROPEAN in real life production of air springs and tires and can be demonstrated on pictures, drawings and videos.

The overall dimensions of the system are approx. 10 x 10 meters. All the air spring components are automatically centered, precut to length in the servicers and automatically applied on the drum. Beads can be loaded manually by the operator (there is enough time for that within the 20 seconds cycle time) or automatically by robot, upon request.

The system requires just one operator to supervise the machine and change bobbins when required.

The New Headquarters

February 2013

In the beginning of February 2013, INTEREUROPEAN has moved to the new company headquarters, opened in Como, Italy.

The new company address and phone numbers are:

INTEREUROPEAN S.r.l.

Via Repubblica 21 22070 Grandate (CO) ITALY

Phone: (+39) 031 565403 Fax: (+39) 031 5472170

Tire Technology Expo 2012

INTEREUROPEAN S.r.l. has participated as exhibitor to the Tire Technology Expo 2012 in Cologne, Gemany on February 14-16 2012.

At the exhibition the company has presented the latest machinery designs for PCR/LT tyres, as well as complete machinery range for production of Air-Springs.